These machines are also known as the machine which is used to produce pills, and in pharmaceutical industries these types of machines come under name tablet counters. This is good because businesses will quickly see a shift in the way those tablets you are making for health product companies like pharma, vitamins. Tablet machines manufacture pills so much faster than we both ever could by hand (like a micro amount of the time it would take to create at this scale), so these are godsend in production.

For instance, in the world of tablet manufacturing you have those simple machines that require a human to run them and all way up to more complex machines like automatic rapid release tablets where no person needs even is need to take part. Simple tablet compaction machines have a single part that exerts pressure and squeezes the powder into pill form. While the larger, more feature packed machines may run faster but they are bulky and difficult to work with when these simple user friendly solutions will get your job done. By comparison, more complex machines may include several pressing components and might even be computer controlled so that all pills come out the same size every time.

A tablet press can help businesses to produce more tablets in less time It would be best suitable for companies, who are looking forward towards bulk production of the pills at a single go so that they could meet their customer demands or even deadlines. Machines would be necessary, which would also help minimize waste by preventing fewer pills to get tossed. Exactly finer amount of Powder will fill into a Machine and through tablet machine, Final products more exact in the manufacturing process. It functions in safety standards according to the others, and keeps quality of products.

Collaboration allows for sharing the established technology, which is getting more and more precise in new tablet machines. They are made so that all of the tablets 100 % remains supportive and it making to the standard by using high technology. For instance, when it reforms the powder that is turned into those pills differently then the machine will recalibrate itself based upon how its supposed to run so everything has all port etc. This will also ensure that the pills are always of high quality which is important for companies whose products need to be taken as medical.

Pill manufacturers have to go through an arduous process before the tablet machine was created. These were manually mixed and pills made using a multitude of devices. This process was slow and error-prone which led to different quality of output. This mini(kindle Bs) of tablets. It facilitated the pill-making process, speeding things up and preventing all produced pills from being safe as well meeting certain quality factors.

In case of emergence of beauty products, Today we see tablet machines every where they are used in the industry such as Medicine and Food. These things are necessary to be able to manufacture and pack a lot of items that you will use on a daily basis. These machines are something that most companies need these days not just to cope up with the orders they receive but also for a quality control.

We can also collaborate with a tablet press so that tablets pressed in it will be usable by the people. In fact, the pharmaceutical industry where everything has to be exact is inseparable from this level of precision; each pill at a time specific to its machine. Even a slight mistake in the dosage can even lead to serious harms which are really very important. A tablet attestation helps in this regard as companies certify that their products are safe and running well for a consumer.

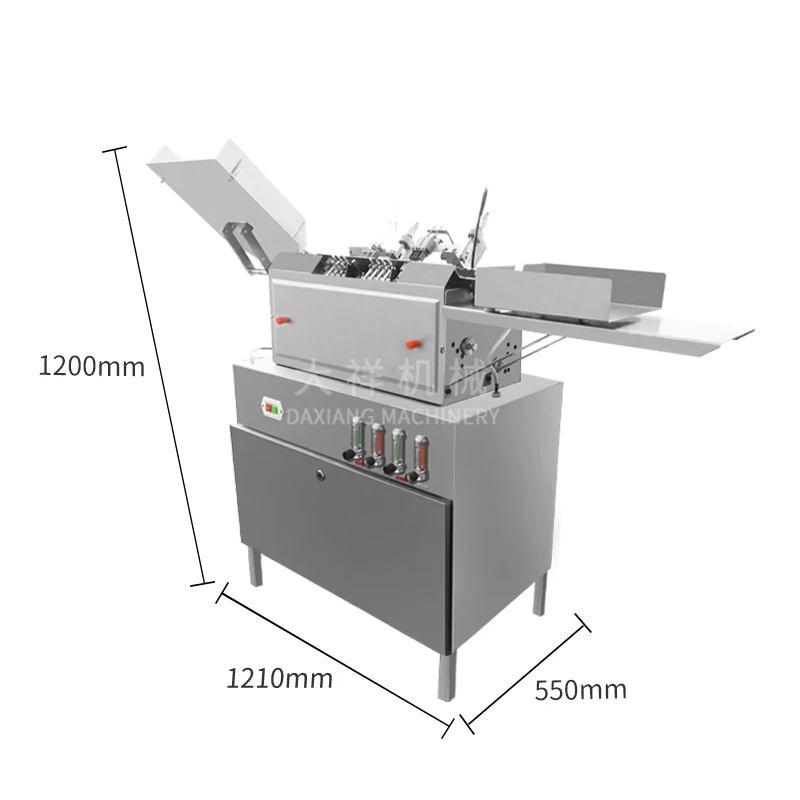

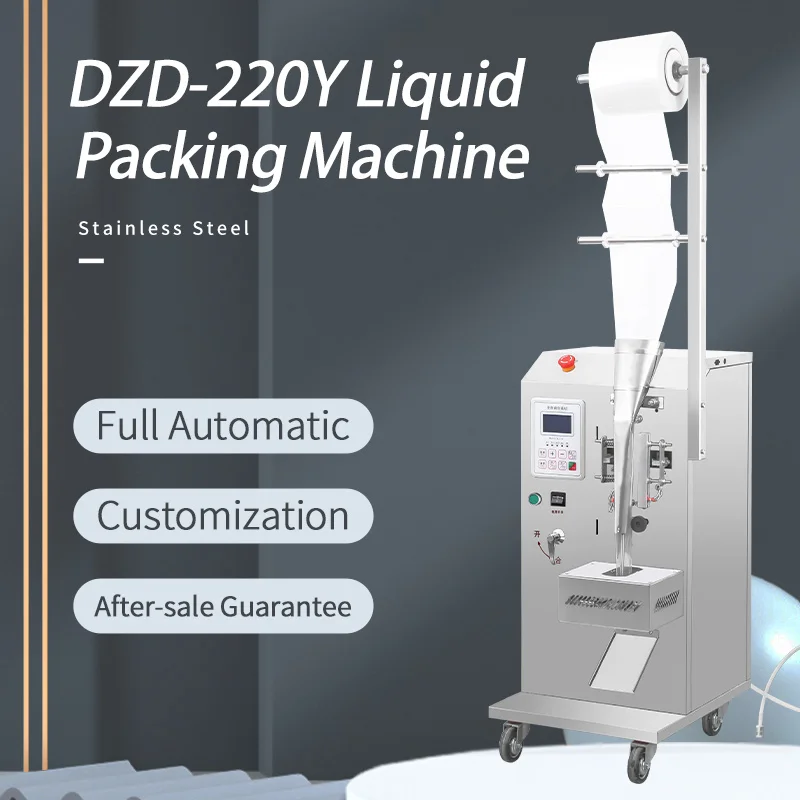

Guangzhou Daxiang a manufacturer of industrial machinery has a manufacturing facility of tablet machine square metres and a warehouse measuring 2 200 square metres we have complete equipment models and sufficient spare parts to satisfy the needs of our customers this machine is extensively used in the packaging and pharmaceutical industries

We have several specialized logistics companies that support tablet machine transport methods and are able of transporting across the globe swiftly, safely easily, efficiently and securely. We provide services to more than thirty thousand customers across the globe and export to more than 100 countries.

In order to improve tablet machine satisfaction, the business offers a 1-year guarantee with lifetime maintenance, as well as remote video or online assistance.

The primary products tablet machine by the firm include Blister Packaging Machines, Tablet Press Machines, Granule Powder Packaging Equipment, Vacuum Packaging Machines, Tablet Counters, Pill Making Machine Coating Machines, Pulverizer Machines, and more.