To be more precise, did you ever give a thought on how those tiny capsules we ingest to heal or replenish ourselves are filled with just the required certain amount of powder or liquid? It’s really interesting! A capsule of a standard filling machine is used to fill these capsules. The 400 capsule filling machine is a good example of this type of equipment and it serves as one crucial factor in the long journey.

The 400 capsule filling machine is so fast and efficient because it uses a unique vacuum system. This system assists in sucking the powder or liquid into capsules, always ensuring an accurate filling. This technology not only saves time, but also food waste and maintains that everything is filled accurately. This is essential for the standard of medicine or vitamins that people use.

The 400 Cap-M-Quik Capsule Filling Machine is really good for handy bulk filling of capsules. It can produce 400 capsules a minute, making it quicker for the companies to make many capsule products in less time. This actually helps them to save money, and even earn more profits for they can provide much goods to their customers!

It is very slow and steady on operating the machine, as it has a motor of good power which operates quickly but with caution to accuracy This motor is extremely long-lasting, so you can continue to produce capsules at an effective rate for many years without concern. One big advantage is that it offers the kind of durability companies interested in producing capsules on a regular basis would need.

Precision is key when it comes to filling capsules. Control system for 400 Capsule Filling MachineThe smart control system of the machine is very high quality, it ensures all capsules are filled with equal amount powder or liquid. This uniformity is particularly important for medications and vitamins, which must be identical in every respect to preserve their standard of quality and efficacy.

Despite its advanced technology, the 400 capsulcnemachine.com/capsule-filling-machine.html is surprisingly very simple to use. Companies will be able to teach their workers how to quickly and effectively manage the machine. All in all, this not only saves time but also aids cost-effectiveness as resources can be brought to pace without much of training.

It is also characterized by a quick changeover design for different products According to Bonner, this allowed companies to change from making one type of capsule product line to another without having disassemble the machine. This saves plenty of time while on production and keeps the machine safe so that it doesn't meet with an accident during a long changeover.

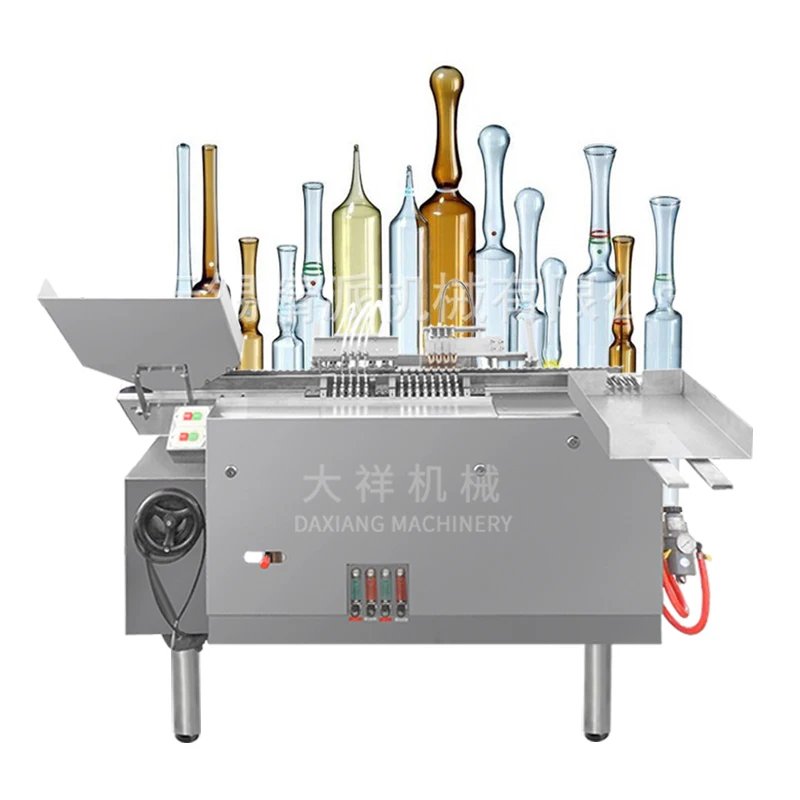

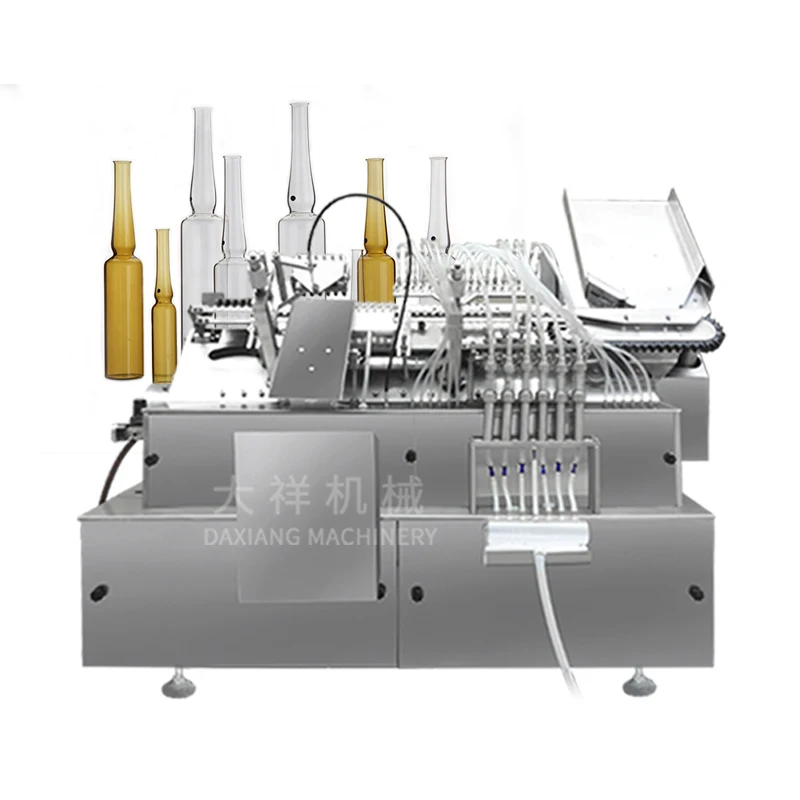

Guangzhou Daxiang a manufacturer is home to a production center with a total area of 3000 square metres as well as a warehouse that measures 2200 square metres we offer complete models of equipment and enough spare parts to satisfy the requirements of our clients it is well-known within the packaging and pharmaceutical 400 capsule filling machine

We have several logistics firms that offer a variety of transport techniques and are able of transporting to 400 capsule filling machine parts of the world quickly, securely, conveniently, and reliably. We provide services to more than 3000 customers in the world, and export to more than 100 countries.

The primary products of the company are 400 capsule filling machine filing machines, Blister Packaging Machine, Tablet Press Machine, Granule Powder Packaging Machine, Vacuum Packaging Machine, Tablet Counting Machine, Pill Making Machine Coating Machine, Pulverizer Machine and many more.

400 capsule filling machine improve customer satisfaction, the company provides a one-year warranty with lifetime maintenance, as well as remote video or online assistance.