Բարձր արագությամբ սեղմման սարքավորումների արագությունն ու կայունությունը հիմնարար ասպեկտներ են, որոնք ազդում են սեղմման գործընթացի արդյունավետության և արտադրողականության վրա: Սեղմիչ սարքերի այս գործոնների բարելավումը կարող է բերել ավելի բարձր կատարողականի և արտադրության ավելացման: Մեքենայի կառուցվածքը, նյութի որակը, սպասարկումը և օպերատորների վերապատրաստումը մի քանի գործոններ են, որոնք նպաստում են արագության և կայունության ձևավորմանը Տաբլետ Պրես Մաքինա . Երբ այս գործոնները օպտիմալ են, արտադրողները կարող են ավելի արդյունավետ և շահութաբեր աշխատել՝ ավելի լավ որակի վերահսկողությամբ:

Որո՞նք են այն պարամետրերը, որոնք ազդում են բարձր արագությամբ սեղմման սարքերի արագության և կայունության վրա

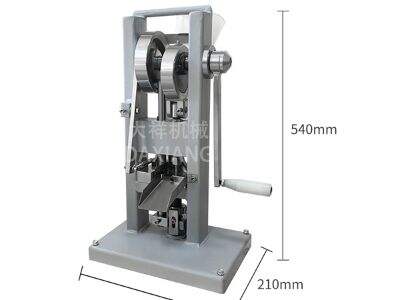

Բարձր արագությամբ սեղման սարքի արագությունն ու կայունությունը որոշող որոշ հիմնարար գործոններ կան: Սարքի կառուցվածքի նախագիծը կարևոր գործոն է, որն ազդում է ամբողջ սարքավորման աշխատանքի վրա: Կառուցման նյութի որակը, որը կարող է լինել ստալինգիտ կամ ալյումին, նույնպես ազդում է արագության և կայունության վրա: Ավելին, փողկալների և մահիճների ճշգրտությունը որոշում է սեղման արտադրության արտադրողականությունը: Սարքավորումը պետք է համարյա մաքրվի և յուղվի՝ անխափան աշխատանքի և դադարի ժամանակի կրճատման համար: Օպերատորի փորձի մակարդակը և վերապատրաստումը նույնպես մեծ ազդեցություն ունեն սարքերի աշխատանքի արագության և դրանց աշխատանքի համաչափության վրա: Խնդրագիրք Սեղմող սարքերը կաշխատեն և դրանց աշխատանքի համաչափության վրա:

Բարելավված արագություն և հուսալիություն սեղմումների սեղմման սարքերի և նմանատիպ սարքերի համար՝ ավելի բարձր արդյունավետության համար

Սեղանի մամլիչի մեքենաների արագությունն ու կայունությունը բարելավելու համար արտադրողները կարող են կիրառել մի քանի մոտեցումներից մեկը կամ մի քանիսը: Բարձրորակ նյութերի ձեռքբերումը և ճշգրիտ մեխանական обработкаն կարող են բարելավել ընդհանուր մեխանիկական հատկությունները: Հիմնական մասերի վնասվածքներից պաշտպանվելու և կայուն աշխատանքի ապահովման համար անհրաժեշտ է հաճախադեպ սպասարկման միջոցառումներ, ներառյալ մաքրում և յուղակալում: Եթե օպերատորները լավ վարպետացած են մեքենաների կարգավորման և խափանումների վերացման մեջ, ապա սա կարող է ավելի արդյունավետ դարձնել արտադրությունը: Կաղապարի և սպեցիֆիկացիաների հատուկ պատվերով մատուցվող ծառայությունները կարող են ավելի շատ արագացնել սեղանի մամլիչի մեքենաների արագությունը և երաշխավորել արտադրության որակը՝ համապատասխանեցնելով հաճախորդների պահանջներին:

Ազդեցությունը բարձրարագ ընթացող տաբլետների սեղմման սարքի վրա

Բարձր արագությամբ սեղմիչների աշխատանքը կարող է ազդվել մի շարք գործոններից, ներառյալ սարքի կառուցվածքը և հավաքումը, կառուցման ընթացքում օգտագործված նյութերի որակը, սպասարկման և շահագործման որակը: Սեղմիչների արագությունն ու կայունությունը զգալիորեն կախված է սարքի կառուցվածքից: Նյութերի օգտագործումը սարքերի կառուցման ընթացքում կարող է ազդել սարքի աշխատանքի վրա և նրա երկարակեցության վրա: Անընդհատ աշխատանքի համար շատ կարևոր է սարքի կանոնավոր սպասարկումը՝ մաքրումը և յուղումը: ցանկապան մեքենա աշխատողի մասնագիտական հմտություններն ու փորձը նույնպես կարևոր դեր են խաղում սեղմիչի հաջող շահագործման և արտադրողականության մեջ:

Բարձր արագությամբ սեղմիչի արագության և կայունության առավելագործում

Բարձր արագությամբ մետաղադրամիջոցի մամուլային մեքենաների ավելի արագ եւ կայուն աշխատանքը ենթակա է ընդհանուր օպտիմալացման: Ավելի լավ մեքենայական աշխատանք կարող է իրականացվել բարձրորակ նյութերի եւ ճշգրտ բաղադրիչների օգտագործմամբ: Սարքավորումների կանոնավոր պահպանումը, օրինակ՝ մաքրումը եւ յուղը, կարող է օգնել խուսափել սարքավորումների անսարքությունից եւ ապահովել գործառույթների անխափան ընթացքը: Կախված այն բանից, թե որքան լավ են վարորդները պատրաստված կարգավորել եւ կարգավորել մեքենաները, պլանշետային մամուլային մեքենաները կարող են ավելի կամ ավելի քիչ արդյունավետ լինել: Մուլտֆիլմերի եւ բնութագրերի հարմարեցման ծառայությունը, ինչպես նաեւ կառավարման վահանակի աջակցությունը կարող են բարելավել արագությունը եւ ամրագրման ժամանակը, որպեսզի մուլտֆիլմերի մամուլը լավ աշխատանքային վիճակում լինի:

Արագություն եւ կայունություն ավելացնելով պլանշետային մամուլում արտադրողականությունը բարձրացնելու համար

Արագացնելով և ստաբիլիզացնելով սեղմակների սեղանի արտադրողականությունը՝ սեղմանների արտադրությունը կարող է ավելի արտադրողական և շահութաբեր լինել: Արտադրողները կարող են հասնել ավելի բարձր ելքի և ավելի լավ վերահսկողության մասերի որակի նկատմամբ՝ կենտրոնանալով մեքենայի կառուցվածքի, նյութի որակի, սպասարկման և օպերատորների վերապատրաստման վրա: Այս ասպեկտների նկատմամբ ավելի լավ վերահսկողությունը կհանգեցնի ավելի հարթ աշխատանքի, ավելի ցածր դադարի և ավելի մեծ արդյունավետության: Արտադրության ընթացքում ձևաչափերի և պարամետրերի հարմարեցումը ըստ պահանջվող սահմանների կարող է օգնել ավելացնել արագությունը և ստաբիլությունը սեղմակների սեղանների համար, ինչը կնպաստի ավելի լավ արդյունքների և ավելի բարձր արտադրողականության:

Առավելագույն արդյունավետություն և արտադրողականություն ստացվում է աղիքավորման սարքավորումների արագությունն ու կայունությունը բարձրացնելու միջոցով: Հաշվի առնելով որոշ փոփոխականներ, ինչպիսիք են սարքավորման կառուցվածքը, նյութի որակը, սպասարկումը և օպերատորների վերապատրաստումը, արտադրողները կարող են օպտիմալ ցուցանիշների հասնել և ավելի շատ արտադրանք շուկա մուտք գործել: Կարիքներին համապատասխան հատուկ ծառայություններ մատուցելով և շարունակական բարելավման վրա հիմնված մոտեցում կիրառելով՝ կարող եք ավելի արագ և կայուն դարձնել աղիքավորման սարքերը՝ ձեր արտադրանքները շահութաբեր դարձնելով և մրցակցային առավելություն ձեռք բերելով: Մենք նաև հնարավորին չափ կփորձենք հաճախորդի պահանջներին համապատասխան, եթե ապրանքի մանրամասների, ձեռնարկի և այլնի կարիք ունեք, կարող եք օգտվել առցանց կամ էլ. փոստային խորհրդատվությունից:

Բովանդակության աղյուսակ

- Որո՞նք են այն պարամետրերը, որոնք ազդում են բարձր արագությամբ սեղմման սարքերի արագության և կայունության վրա

- Բարելավված արագություն և հուսալիություն սեղմումների սեղմման սարքերի և նմանատիպ սարքերի համար՝ ավելի բարձր արդյունավետության համար

- Ազդեցությունը բարձրարագ ընթացող տաբլետների սեղմման սարքի վրա

- Բարձր արագությամբ սեղմիչի արագության և կայունության առավելագործում

- Արագություն եւ կայունություն ավելացնելով պլանշետային մամուլում արտադրողականությունը բարձրացնելու համար

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LV

LV

SR

SR

SL

SL

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

GA

GA

BE

BE

IS

IS

HY

HY

BN

BN

LO

LO