The economy is bad, but not so much that pharmaceutical companies are now struggling to make medicine to help people feel better. They have to make certain that everybody is receiving treatment in the best and most appropriate place. They fill capsules using a special machine that measures the correct dose. This crucial device is called a capsule filling machine.

A capsule is a small container that holds the medicine inside. This is a very small pill that seems to be in the shape of two pieces, which fit together absolutely perfectly. The capsule itself would be formulated using "special" material that can dissolve in our bodies. Altogether, this results in breakdown of the capsule so that our body can release the medicine and help us feel better when we take it.

If you still wish to proceed with a machine, do it often (once every other week) as manufacturing is the best way to guarantee that each capsule contains the same amount of drugs. It is very important because this can help patients to take the right amount of medicine in order for them to get well and keep good health. A person who takes too little of their medicine may not notice a difference, and they might mistakenly conclude that the medication was never effective at all; but on the otherhand if someone has a bit much it can lead to great harm as well.

One other crucial rule is with the medicine proper dosage per tablet And it is a problem for the person who takes the medicine if too much of it. If too little can be as good as doing nothing at all. Capsuls should also be kept in a cool, dry area This ensures that they do not malfunction or lose their vitality for decades to come.

In the case of capsule filling machines, a company is interested in ensuring that every single capsule has an equal amount: dose. This means that the machine must be tared properly to perform at optimum functionality. Calibration is a big word but simply means that everything has to be set right so the machine delivers the capsules dosage correctly.

The new technology existing in the machines company is making available for this capsule production, helping them to improve their process. Hundreds of capsules can get filled in one go by some machines! This with help to save time and prevent any errors. Also, some of them also have those special sensors in machines to ensure somehow when something is wrong. These sensors optimise to avoid errors which is even more important as medication can be made safer and quicker.

You can follow these safety rules, among other things, by using a good capsule fillling machine That means selecting a unit that is from an established company and adheres to all required safety guidelines and quality control. Further, maintaining and servicing the machine is also very important. The purpose of this is to guarantee that the machine remains in good condition through out its life, and produces medicine safe for everybody.

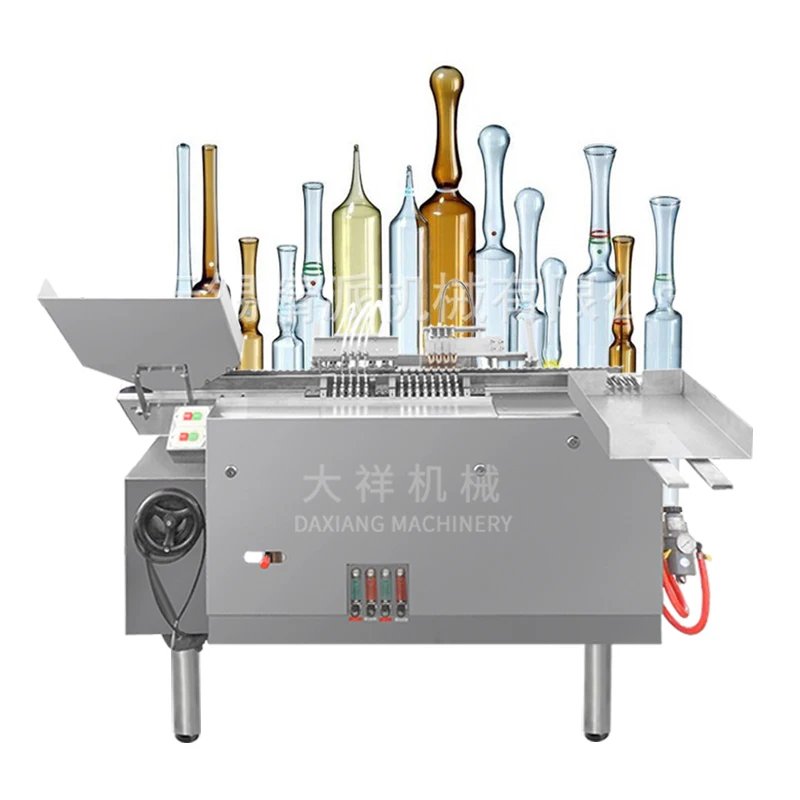

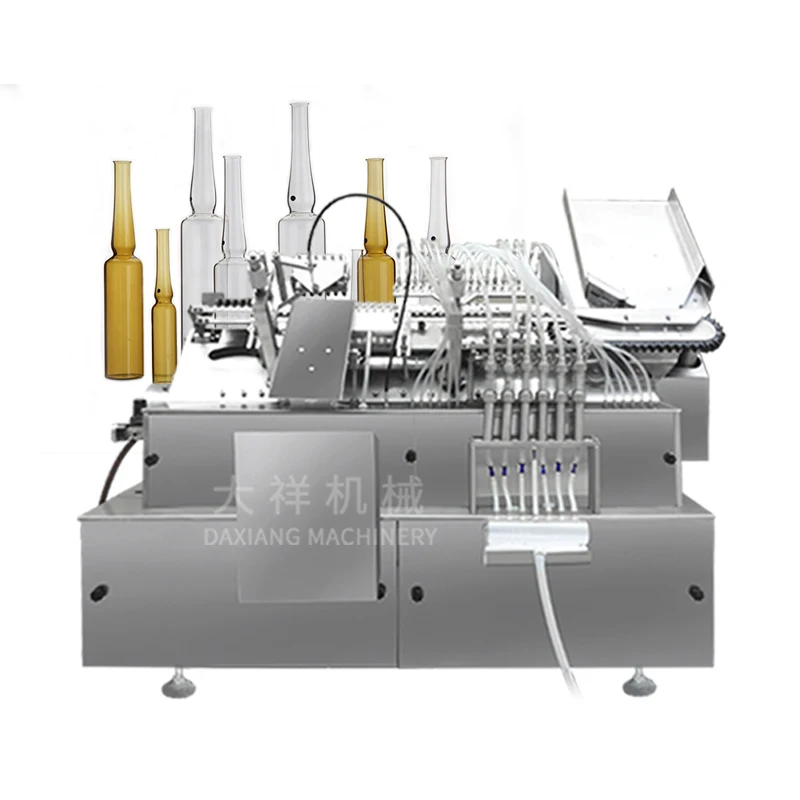

The Pharmaceutical Capsule Filling Machine products offered by the company are Capsule Filing Machines, Blister Packaging Machines, Tablet Press Machines, Granule Powder Packaging Machines Vacuum Packaging Equipment, Tablet Counters, Pill Making Machine Pulverizer Machines, Coating Machines and many more.

To improve customer satisfaction, the company offers a Pharmaceutical Capsule Filling Machine year warranty that includes lifetime maintenance as well as remote video or online assistance.

Our logistics companies are specialized in a variety of transportation methods. They can move products to various parts of the world quickly, Pharmaceutical Capsule Filling Machine, conveniently and reliably. We offer services to over 3000 customers in the world, and export to more than 100 countries.

Guangzhou Daxiang a manufacturer is home to a production center with a total area of 3000 square metres as well as a warehouse that measures 2200 square metres we offer complete models of equipment and enough spare parts to satisfy the requirements of our clients it is well-known within the packaging and pharmaceutical Pharmaceutical Capsule Filling Machine