It is made by the Rotary Tablet Press Machine, and that machine is an amazing tool for preparing these tablets which are medicines provided to people. It is a unique equipment which prepares tablets at once very quickly. What it means is that public can gets their medicines on time, which indeed are the most important factor in one's health.

Rotary Tablet Press Machine - This type simply compress powder into Tablets It does this by wrapping that powder up really tight like the biggest bear hug ever. After compacting one pile of powder, it jogs over to the next pile and repeats. Since it is very fast, it can produce the tablets in an even shorter time. It provides immediate relief to anyone that needs their medicine fast due to how quickly it works. The device allows high-quality tablet manufacturing as well. A special mold that presses the powder so perfectly every tablet is identical in size and form. This can be very good when the tablets have to become packaged and swallowed quickly.

These machines such as the Rotary Tablet Press Machine is very sturdy and lasts for a long time. Not a lot of repairs or maintenance required, so that is ideal for the workers. The machine is built to handle some moving things and those items are heavy duty. As a website is up for 24/7 thus this way machine never gets in trouble or stop working, It is also very easy to clean up, which makes it even better. It is very significant as now and then diverse sort of tablets must be produced. Ease of cleaning will ensure your machine remains clean and hygienic.

The Rotary Tablet Press Machine can produce tablets in a very accurate manner and it is one of the things, so many people find good about this machine. It features a special tool called dosing disk. This tool requires the same amount of drug in each tablet. This is significant because many medicines need only a certain amount to be effective. If incorrect it will not be of any use to the person in need. The dosing disk ensures that every single tablet is alike, which can be especially important for patients who rely on them to get well again.

The machine is very flexible in that you can produce a variety of different types of tablets on one Rotary Tablet Press Machine. You might also need that swirl to be round, oval or heck even square. The machine can handle those shapes with no difficulty. It can even manufacture tablets in various colours as well designed coatings etc. This is great because some meds go down smoother if they are enter-cared. This coating potentially makes the tablets easier to swallow and also reduces bitterness.

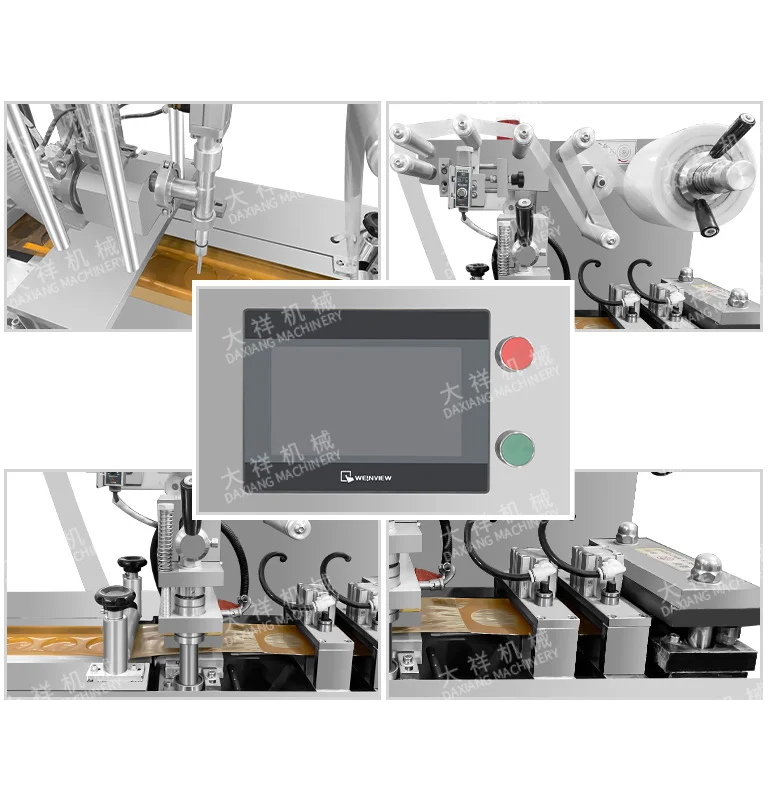

Safe and reliable Rotary Tablet Press Machine. Made of durable materials so it can last for a long time before any problem starts happening. Furthermore, the machine is made so as to not injure anyone. This includes guards over the moving parts. The guards are installed to keep the people safe and avoid any kind of accidents. It is vital in a compact factory where many people are together working.

To increase customer satisfaction, the Rotary Tablet Press Machine provides a one-year warranty for maintenance and a lifetime remote online or video support.

The Rotary Tablet Press Machine products offered by the company are Capsule Filing Machines, Blister Packaging Machines, Tablet Press Machines, Granule Powder Packaging Machines Vacuum Packaging Equipment, Tablet Counters, Pill Making Machine Pulverizer Machines, Coating Machines and many more.

We have several specialized logistics companies that support Rotary Tablet Press Machine transport methods and are able of transporting across the globe swiftly, safely easily, efficiently and securely. We provide services to more than thirty thousand customers across the globe and export to more than 100 countries.

Guangzhou Daxiang is a manufacturer with a production facility that covers 3000 square metres and a warehouse of 2200 square meters we offer complete models of equipment and spare parts that are sufficient to satisfy the requirements of our customers this machine is Rotary Tablet Press Machine used in the packaging and pharmaceutical industries